Modular Building Surfaces

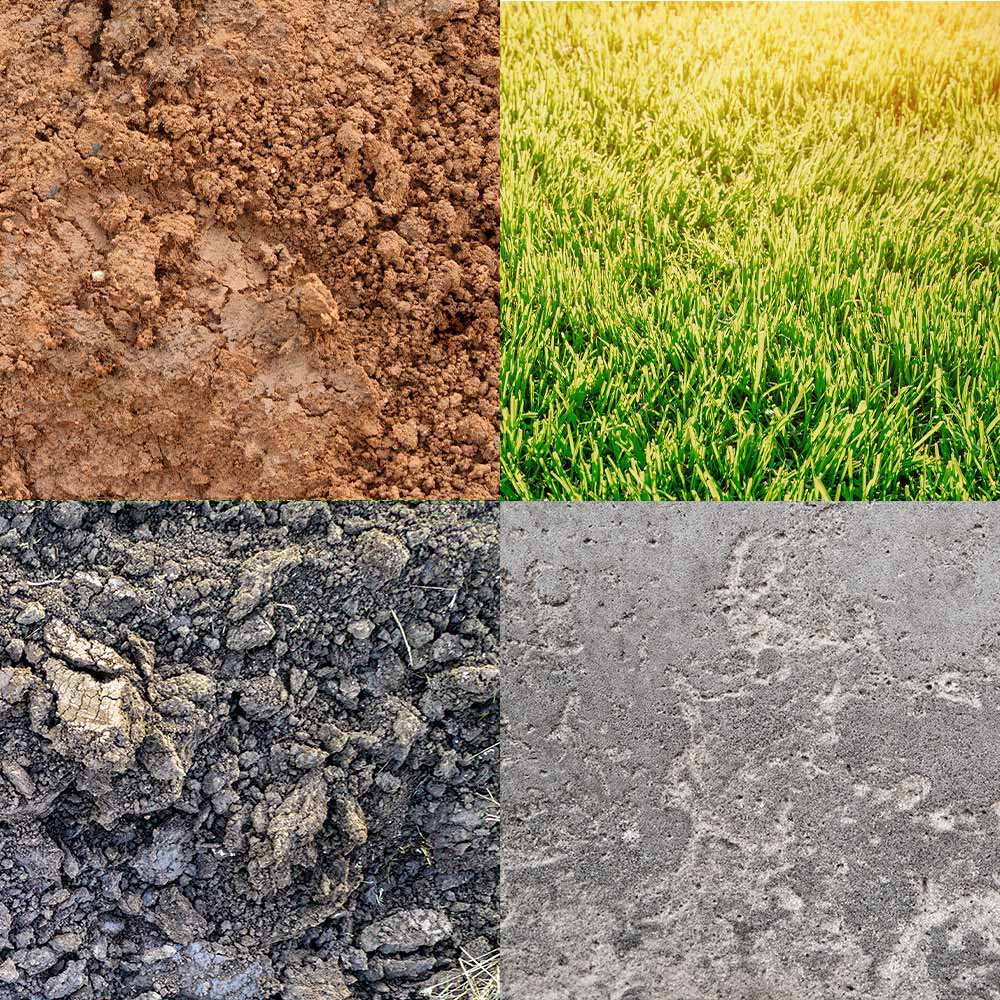

From educational facilities to retail spaces and residential units, SmartPod’s range of modular buildings offer a versatile, sustainable, and efficient solution for various needs. However, the success of these structures often hinges on the foundation upon which they are built. Due to our integration of RADIX Ground Screws, SmartPods offer an adaptable and eco-friendly alternative for supporting modular buildings on diverse surfaces. For instance, our installation provides secure foundations in soft soils like loamy fields, where traditional methods may falter. In unpaved settings, such as grassy parks, ground screws minimise ecological disruption. They can also be effectively used in hard soil environments, like rocky hillsides, through pre-drilling, ensuring stability where conventional foundations might struggle. In waterlogged areas, such as marshlands, specially designed screws offer durability and prevent structural shifting. On paved surfaces, like urban concrete lots, ground screws can be used with minimal disruption, making them an efficient choice for urban installations. These diverse applications highlight the versatility of ground screws in accommodating various terrains and construction challenges, making them a go-to choice for modular buildings.

RADIX Ground Screws

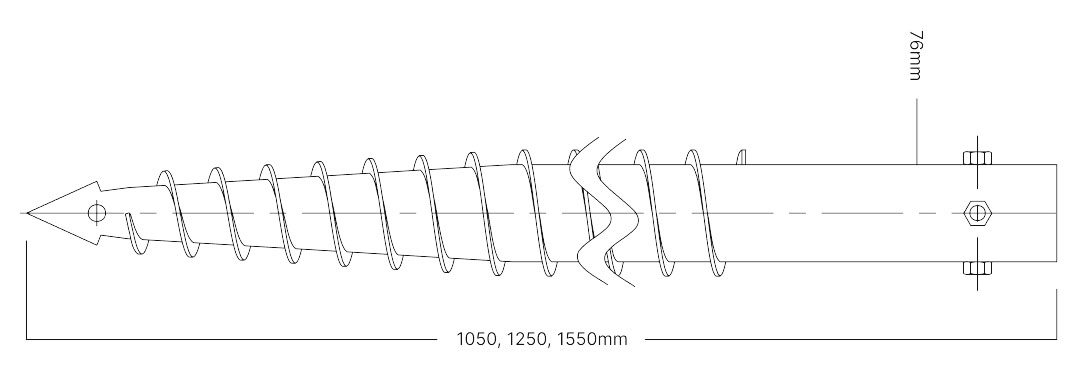

RADIX Ground Screws represent a modern, eco-friendly alternative to traditional concrete foundations. Engineered from high-quality galvanised steel, these screws are designed to provide a strong, secure, and durable foundation for a wide range of structures. With their versatility, load-bearing capacity, and long lifespan, RADIX Ground Screws offer numerous advantages over traditional foundation methods. SmartPods work exclusively with the RADIX ground screw, meaning we can install modular buildings on almost any surface.

Time Efficiency: One of the key benefits of RADIX Ground Screws is their quick and easy installation process. Unlike concrete foundations, which require time for excavation, pouring, and curing, ground screws can be installed in a fraction of the time. This allows for rapid deployment of modular buildings, reducing project timelines and labor costs. Ground screws are typically 70% faster to install compared to traditional concrete foundations, making them an ideal choice for projects with tight schedules.

Versatility: Ground screws can be installed on a wide variety of terrains, including sloping, uneven, and soft ground. This versatility makes them suitable for remote and hard-to-access areas, where traditional foundations may be impractical. Additionally, ground screws can be installed in any weather conditions, providing flexibility for year-round construction.

Immediate Load-Bearing Capacity: Once installed, RADIX Ground Screws provide immediate load-bearing capacity, eliminating the need for curing time required by concrete. This allows for immediate construction and occupancy of modular buildings, further reducing project timelines and costs.

Durability and Longevity: RADIX Ground Screws are engineered for longevity, with a life expectancy of over 60 years and a 35-year guarantee. Made from high-quality galvanized steel, they are resistant to corrosion and wear, ensuring a stable and durable foundation for years to come.

Frequently Asked Questions

The integration of modular buildings with RADIX Ground Screws offers a revolutionary solution for modern construction projects. By providing a quick, eco-friendly, and versatile alternative to traditional concrete foundations, ground screws enable modular buildings to be installed on a wide range of terrains. From soft soils and unpaved surfaces to hard soils and waterlogged areas, ground screws offer a reliable and durable foundation solution that meets the diverse needs of modern infrastructure projects.

Whether you’re looking to install a modular building in a remote rural area or a bustling urban environment, SmartPods provide the flexibility and adaptability you need. By minimising environmental impact and reducing project timelines, our integration of ground screws ensure that your modular building is secure, stable, and sustainable.

For more information on how a modular building can transform your construction projects, contact us today to discuss your needs and receive a personalised quote. We look forward to helping you create the ideal modular building solution, regardless of the terrain.